From Concept to Concrete

Boldly Shaping the Future of Concrete

At möbius™, we believe the story behind the product is just as important as the product itself. Every form we create is born from a rigorous, innovative process that combines advanced technology, artisan craftsmanship, and an obsession with detail. Here’s how we bring impossible objects to life.

Where Technology Meets Sculpture

3D Concrete Printing

Our proprietary 3D concrete printing process allows us to fabricate complex, sculptural forms that traditional casting could never achieve. With precision layering, material efficiency, and limitless design flexibility, we turn digital models into tangible works of art—layer by layer, line by line.

Beyond aesthetics, 3D concrete printing offers a more sustainable path forward. By building only what’s needed, exactly where it’s needed, the process minimizes material waste, reduces mold dependency, and lowers emissions associated with traditional casting. This method also enables lighter structures with superior performance, making it ideal for modern architectural demands—from bespoke furniture to integrated urban solutions.

Timeless Strength, Cast by Hand

Cast GFRC

Glass Fiber Reinforced Concrete (GFRC) gives us the ability to mold elegant, architectural shapes with strength and durability far beyond traditional concrete. Using hand-poured techniques and high-performance mixes, our cast GFRC process yields pieces with crisp lines, subtle textures, and exceptional resilience.

GFRC also offers significant environmental advantages. Its lighter weight reduces transportation emissions and structural load requirements, while its thin, high-strength profile requires less raw material per piece. This results in concrete products that are not only more adaptable and long-lasting, but also more efficient to produce—supporting lower-impact design across both indoor and outdoor applications.

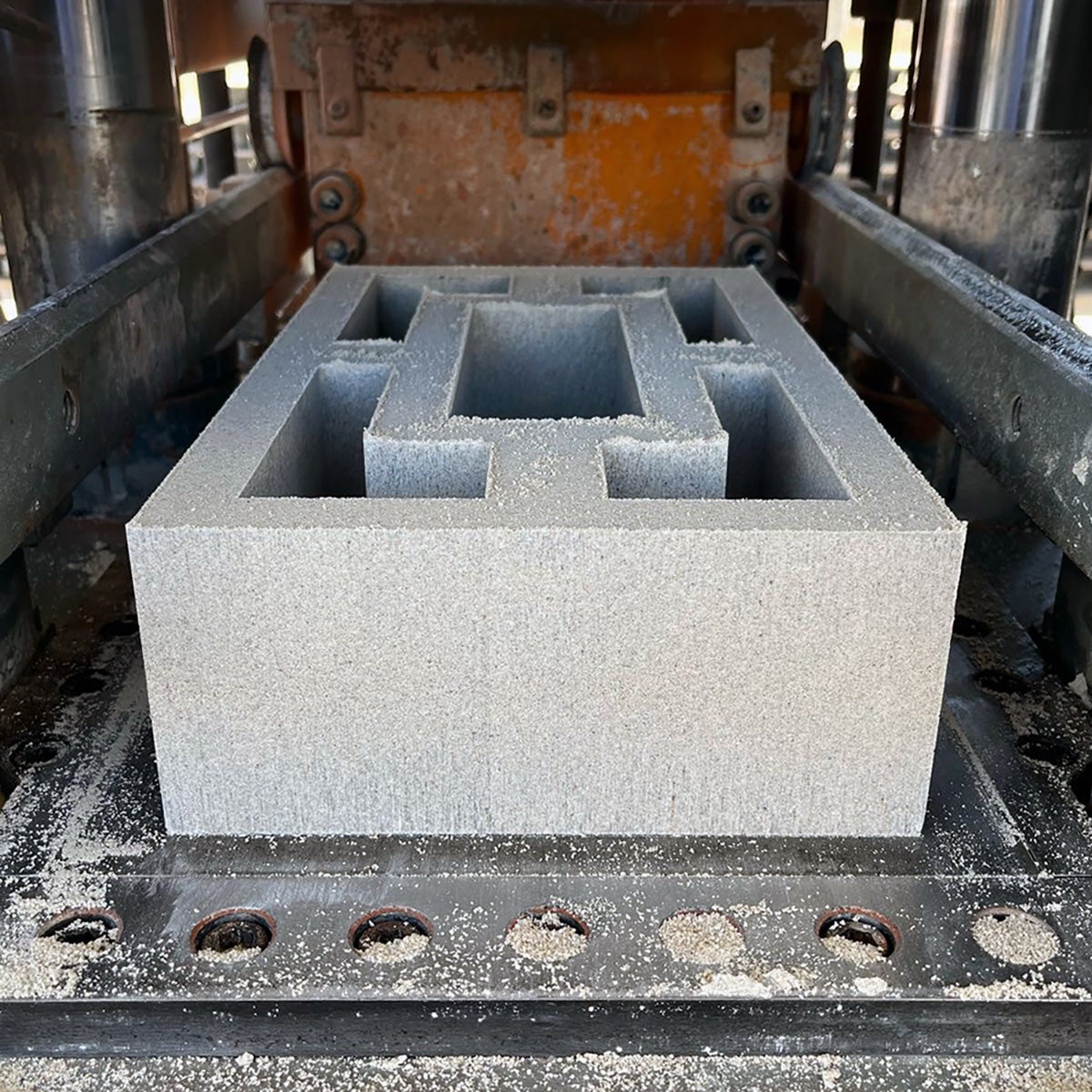

Extreme Compression, Extraordinary Results

Hyper-Press

Our hyper-press process applies immense pressure to produce ultra-dense concrete products with a refined surface finish and superior structural integrity. The result is a tactile, elegant material that feels just as elevated as it looks—perfect for modern environments that demand more from every detail.

This process not only enhances durability and surface clarity, but also improves environmental performance. By compacting material at a microscopic level, we reduce porosity, extend product lifespan, and eliminate the need for chemical sealers. The hyper-pressed method also supports thinner profiles with greater strength, allowing for more efficient use of raw material without compromising aesthetics or longevity.

Why It Matters

We Don’t Just Make Products — We Enable Projects

Each Mobius piece is engineered to integrate seamlessly into the built environment. Whether you're specifying materials for a boutique hotel or customizing a courtyard installation, our process is built for collaboration — with the design professional at the center.